The Ultimate Guide to Understanding Geogrid Material for Construction Success

Table of Contents

- What is Geogrid Material and Why It Matters in Construction

- Key Benefits of Using Geogrids in Civil Engineering Projects

- Different Types of Geogrid Materials and Their Applications

- Top Tips for Selecting the Right Geogrid for Your Project

- Installation Best Practices for Maximum Geogrid Performance

- Common Challenges and Solutions When Using Geogrids in Construction

- Essential Guide to Choosing the Right Guide Needle for Your Medical Procedures

- FAQS

- Conclusion

- Related Posts

You know, in the world of civil engineering and construction, geogrid materials have really become a game-changer when it comes to making soil more stable and strengthening structures. I’ve seen reports saying that the global market for geosynthetics is expected to surpass $10 billion by 2025 — pretty impressive, right? And geogrids are a big part of that growth because they do an excellent job at reinforcing soil and stopping erosion. At DANYANG YIXUN MACHINERY CO., LTD, we’re proud to be a leading manufacturer of both multiaxial and biaxial warp knitting machines. We specialize in creating top-quality geogrid materials that are essential for projects like road building, retaining walls, and stabilizing slopes. Thanks to our advanced knitting technology, our products are built to perform well and last long — because more than ever, the need for reliable soil reinforcement solutions is on the rise.

What is Geogrid Material and Why It Matters in Construction

In today’s really competitive world, navigating the complexities of the supply chain when it comes to sourcing

geogrids is more important than ever. A recent report from

Smithers Pira shows that the global market for geogrids is expected to grow at about 6.5%

annually between 2023 and 2028. That’s mainly because construction and civil engineering projects are more in

demand than ever. But here's the thing — finding top-quality geogrid materials can be pretty tricky. Different

countries have their own standards and rules, which can make the whole procurement process a real headache,

especially for buyers operating internationally.

One of the biggest challenges? The inconsistency in quality and

specifications across different suppliers. The same report from Smithers Pira mentions that nearly

30% of procurement pros worry a lot about quality assurance

when they’re sourcing geogrids from overseas. On top of that, geopolitical issues and disruptions in logistics can

throw a wrench in the works, causing delays that can mess with project deadlines and budgets. So, it's super

important for buyers to build strong relationships with certified manufacturers and stay on top of market

trends. That way, they can better manage these risks and make sure they get the right geogrid materials

without too much hassle.

Key Benefits of Using Geogrids in Civil Engineering Projects

You know, these days, geogrids are really gaining ground in civil engineering projects. People are starting to see just how important they are for strengthening soil and making structures more stable and durable. Actually, a report from the Federal Highway Administration (FHWA) shows that when you use geogrids, you can cut down the amount of aggregate you need by anywhere from 30% to 50%. That’s a pretty big deal because it saves on materials and keeps things running more smoothly and cost-effectively. Plus, with geogrids helping to spread out the load better and keep lateral movement in check, infrastructure tends to last way longer and hold up better over time.

At DANYANG YIXUN MACHINERY CO., LTD, we’re all about making the best knitting machines for geogrid production. Our multiaxial and biaxial warp knitting machines are top-notch and help produce high-quality geogrids that modern construction really relies on. These geogrids aren’t just strong—they actually boost the load-bearing capacity of foundations thanks to their improved tensile strength. And because they’re lightweight but super sturdy, they’re perfect for a variety of projects—think roadways, retaining walls, you name it. Honestly, using geogrids can even extend the lifespan of roads by up to 50%, so they’re a game-changer for civil engineering works.

Different Types of Geogrid Materials and Their Applications

You know, geogrid materials are pretty much essential in modern construction these days, especially when it comes to reinforcing and stabilizing soils. There are a few main types—unaxial, biaxial, and multiaxial—each suited for different jobs. For example, uniaxial geogrids are often used in retaining walls or on steep slopes since they offer strong tensile support in just one direction. Biaxial geogrids are more like the jack-of-all-trades—they’re great for road building and stabilizing the ground underneath, because they distribute loads in two directions pretty effectively. Then there are the multiaxial ones, which are a bit more complex—they give support in multiple directions and are perfect for stuff like slope protection or earth embankments. They really help reduce settlement and make everything way more stable.

Now, according to a report from Grand View Research, the global market for geogrids is expected to hit around USD 1.64 billion by 2025. That growth is mainly driven by increasing demand in infrastructure projects worldwide. The cool thing is, geogrids help improve soil performance and cut down construction costs, which is why more and more folks are jumping on board. Over here at DANYANG YIXUN MACHINERY CO., LTD, we’re all about cutting-edge knitting tech—our machines are super advanced and produce top-notch multiaxial and biaxial warp knits. We’re geared toward helping manufacturers meet the rising demand for quality geogrids, providing innovative solutions to tackle construction challenges. It’s really a perfect combo of tech and material that’s crucial for successful engineering projects.

Top Tips for Selecting the Right Geogrid for Your Project

Starting a construction project? Picking the right geogrid is actually pretty important if you want things to stay stable and last a good long time. Basically, geogrids—usually made from synthetic stuff like polyester or polypropylene—are meant to strengthen the soil and spread out the load more evenly. I came across this report from MarketsandMarkets that says the global market for geogrids is expected to hit about 1.9 billion USD by 2025. That growth is mainly because more folks are realizing how these materials can make civil engineering projects more sustainable and safer. Pretty cool, right?

If you're trying to figure out which geogrid to go with, think about a few key things like what material it’s made of, how much tension it can handle, and what kind of job you’re working on. For tougher soil conditions, multiaxial geogrids—like the ones from DANYANG YIXUN MACHINERY CO., LTD—tend to perform much better. And, according to the Geosynthetic Materials Association, using top-quality geogrids can cut down settlement problems by up to half. So, it really pays to pick the right one that fits your project’s needs—that way, you get better results and save some money too.

Installation Best Practices for Maximum Geogrid Performance

When you're trying to get the most out of geogrid materials in construction projects, understanding the best ways to install them is pretty important. Using a high-strength geocell with a geogrid hybrid reinforcement can really make a difference, especially for things like heavy gravel pads at compressor stations. This kind of hybrid setup doesn’t just give you sturdy support; it also helps the soil work better with the reinforcement, which means the load gets spread out more evenly across the site.

Here's a pro tip—before you start laying down the geogrid, make sure the base is all set and proper. A well-graded aggregate base acts like a solid foundation, and that really helps the geogrid do its job properly. Also, keep an eye on aligning the geogrid correctly during installation. It might seem small, but it helps prevent slipping and ensures loads transfer smoothly.

Another thing to watch out for is how you overlap and connect different sections of the geogrid. Overlapping them correctly helps distribute the weight better and cuts down on the risk of deformation when heavy stuff is on top. Taking a moment to double-check those connections can pay off big time — you'll end up with a reinforcement that's not just durable, but also much more effective, especially in tough environments like retaining walls or heavy equipment pads.

Common Challenges and Solutions When Using Geogrids in Construction

Geogrids have pretty much become a go-to in construction when it comes to soil reinforcement. But, let’s be honest—they’re not without their hiccups. One common problem is how they get installed; if it’s not done properly, it can really mess with how well the geogrid does its job. If you don’t lay it down just right, it might not give the support you’re counting on, which could lead to soil erosion or even the structure failing. To avoid that mess, construction crews should really invest time in proper training and use some of the latest alignment techniques to make sure everything’s placed exactly where it needs to be.

Another thing folks often overlook is picking the right geogrid for the soil and the project. A lot of contractors might think a one-size-fits-all approach works fine—trust me, it doesn’t. Soils can act pretty differently depending on where you are, and choosing the wrong type of geogrid can seriously compromise the performance. The best bet is to do a detailed soil analysis before starting the project. Plus, working with knowledgeable suppliers can make a big difference—they can help you pick the right geogrid that matches both the environmental conditions and what you’re trying to achieve with the build.

Essential Guide to Choosing the Right Guide Needle for Your Medical Procedures

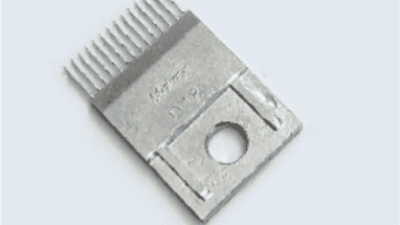

Choosing the right guide needle for your medical procedures is crucial for ensuring precision and patient safety. With a variety of options available, each designed for specific applications, understanding the differences among them can help you make informed choices tailored to patient needs. The guide needles E9, E10, E12, E14, E16, E18, E20, and E22 each have unique features that cater to various medical scenarios.

For instance, the E9 and E10 needles are excellent for less invasive procedures where precision is key, providing excellent control during access. As you move up to needles like the E14 and E16, they offer greater gauge options, making them suitable for more demanding tasks. The larger E18, E20, and E22 needles can accommodate larger volumes and are ideal for procedures that require swift fluid transfers or biopsies. It's important to weigh factors such as gauge size, length, and the intended application to select the most appropriate guide needle.

Ultimately, selecting the right guide needle can significantly enhance the effectiveness of the procedure being performed. Practitioners should assess the specific requirements of each case to choose from the E9 to E22 range effectively, ensuring optimal outcomes for their patients while maximizing procedural safety.

FAQS

: Geogrid materials enhance soil stabilization by distributing loads across a broader area, reducing stress on the underlying soil, preventing deformation or failure, improving drainage, and reinforcing the soil structure.

By integrating geogrid into road construction, engineers can significantly improve the structural integrity of pavements, allowing them to withstand heavy traffic and resulting in reduced maintenance costs over time.

Geogrid is especially useful in road construction and projects in areas prone to shifting or saturating soils, as it creates a stable framework that resists erosion and lateral movement.

Proper site preparation, which includes compacting base layers and ensuring the surface is level and free of debris, is essential for maximizing the interaction between geogrid and surrounding soil, leading to a more stable foundation.

Assessing the type of soil present at the site is crucial, as different soil characteristics can significantly affect the performance and effectiveness of the geogrid.

Best practices include ensuring proper alignment and overlap during installation, using suitable backfill material that complements the geogrid’s capabilities, and gradually adding backfill while compacting to enhance integration with the soil.

Yes, geogrids are versatile and can be used in conjunction with various materials, such as gravel and concrete, allowing for tailored solutions to meet specific project needs.

The use of geogrids leads to smarter construction practices that optimize resource use, ultimately ensuring durable and reliable infrastructure with reduced environmental impact.

Misalignment during installation can create weak points where the soil may fail under pressure, highlighting the importance of proper alignment and overlap.

Following proper installation techniques significantly optimizes the performance and longevity of geogrid systems, enhancing soil stability for various applications.

Conclusion

You know, geogrid materials have really become a game-changer when it comes to boosting soil stability in all kinds of projects. It's pretty important to get what makes these materials tick if you want to use them effectively. Basically, geogrids help lock soil particles together and spread out loads, which makes structures way stronger. There are different types of geogrids out there, each suited for specific needs—so picking the right one depends a lot on the soil you're working with and the environmental conditions, you know?

Getting the installation right is also super important if you want your geogrids to perform at their best. Following some best practices can make all the difference and really boost your chances of success. There are tons of case studies showing how well geogrid solutions work across various industries — it’s pretty impressive how versatile and effective they can be. And as technology keeps advancing, we’re all excited about future innovations that'll make soil stabilization even better. At DANYANG YIXUN MACHINERY CO., LTD, we’re dedicated to providing top-notch warp knitting machines that help produce all sorts of geogrid materials—supporting growth and innovation in this field, no doubt about it.