Factory wholesale Basalt Fiber Geogrid - FC(ll)Chopped Stitch Bonding Machine – Yixun

Factory wholesale Basalt Fiber Geogrid - FC(ll)Chopped Stitch Bonding Machine – Yixun Detail:

*This machine is used for producing chopped strand mat,compound mat

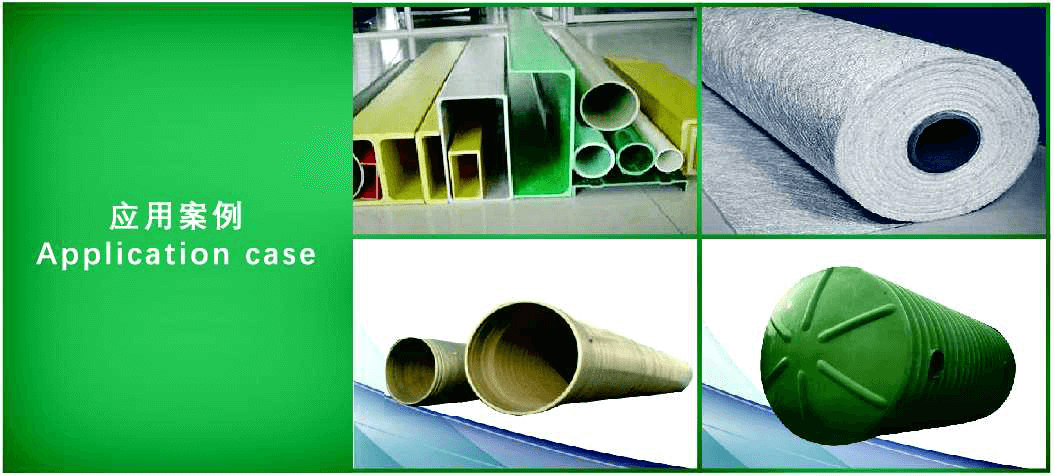

Application Case

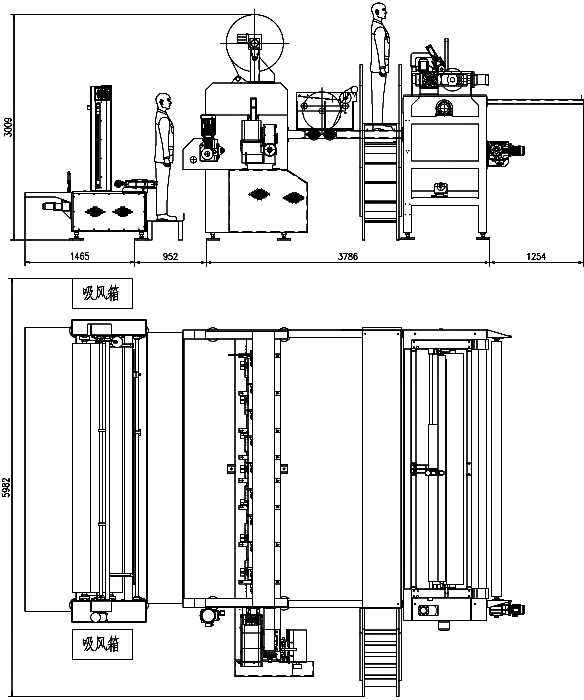

General assembly drawing

Specifications

| Width | 116 inches |

| Gauge | E7 |

| Speed | 50-1300r/min (The specific speed depend the products.) |

| Bar Number | 1 Bars |

| Pattern Drive | Pattern Disc |

| Warp Beam Support | 30 inches beam.EBC |

| Take-up Device | Electronic Take-up |

| Batching Device | Friction Batching With Press Roller |

| Chopped Device | 1 Chopped Device,Servo System Controlling. |

| Feeding Equipment | Parallel feeding Servo System Controlling |

| Power | 15kW |

|

This type’ s machine could be personal designed |

|

Product Video

Your browser does not support video tags.

Product detail pictures:

Related Product Guide:

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Factory wholesale Basalt Fiber Geogrid - FC(ll)Chopped Stitch Bonding Machine – Yixun , The product will supply to all over the world, such as: Norwegian, United Arab emirates, Albania, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We've got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

Write your message here and send it to us