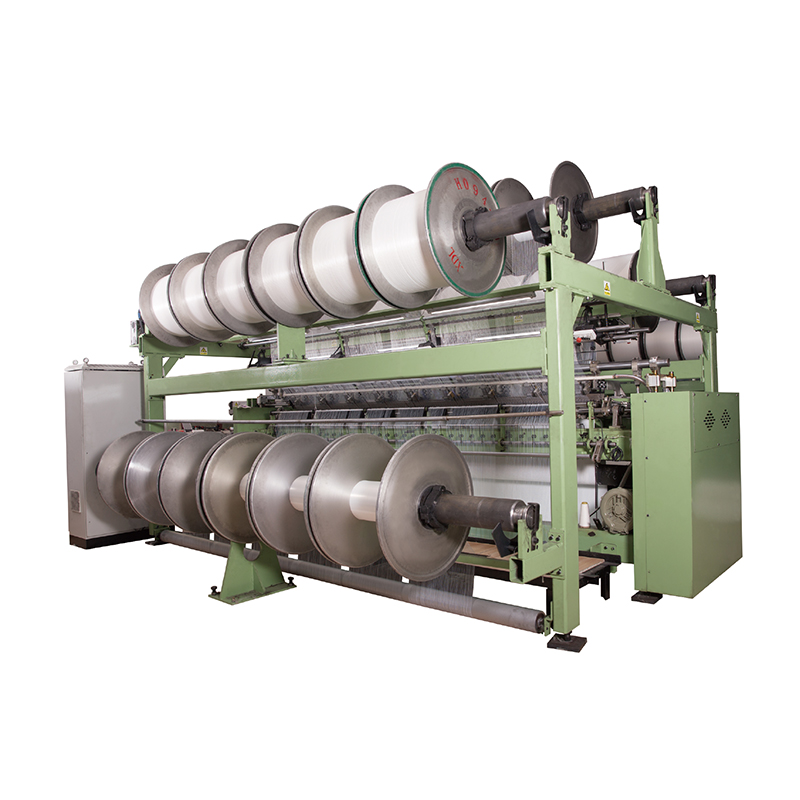

Manufacturer of Chopped Strand Mat Manufacturing Process - YRS3-M-F-II Chopped Biaxial Warp Knitting Machine – Yixun

Manufacturer of Chopped Strand Mat Manufacturing Process - YRS3-M-F-II Chopped Biaxial Warp Knitting Machine – Yixun Detail:

*Used for producing full width weft insertion chopped mat and composite fabric

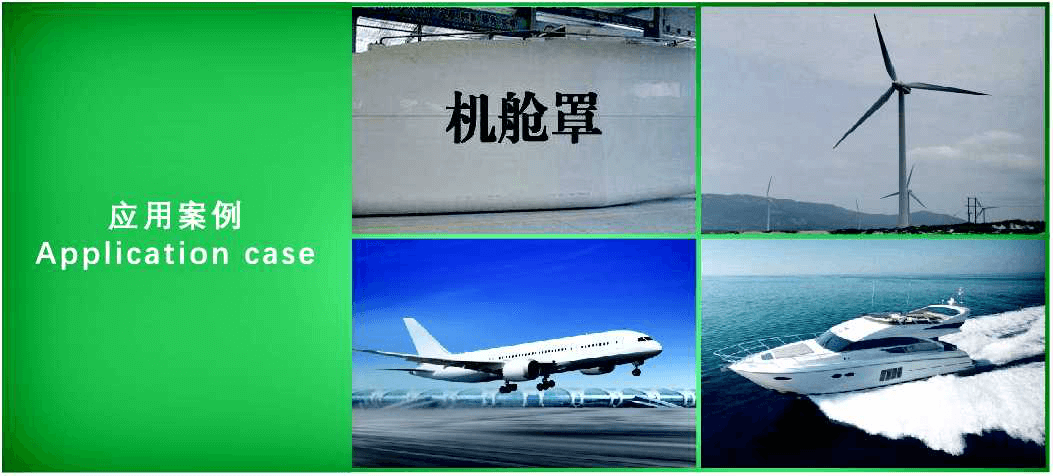

Application Case

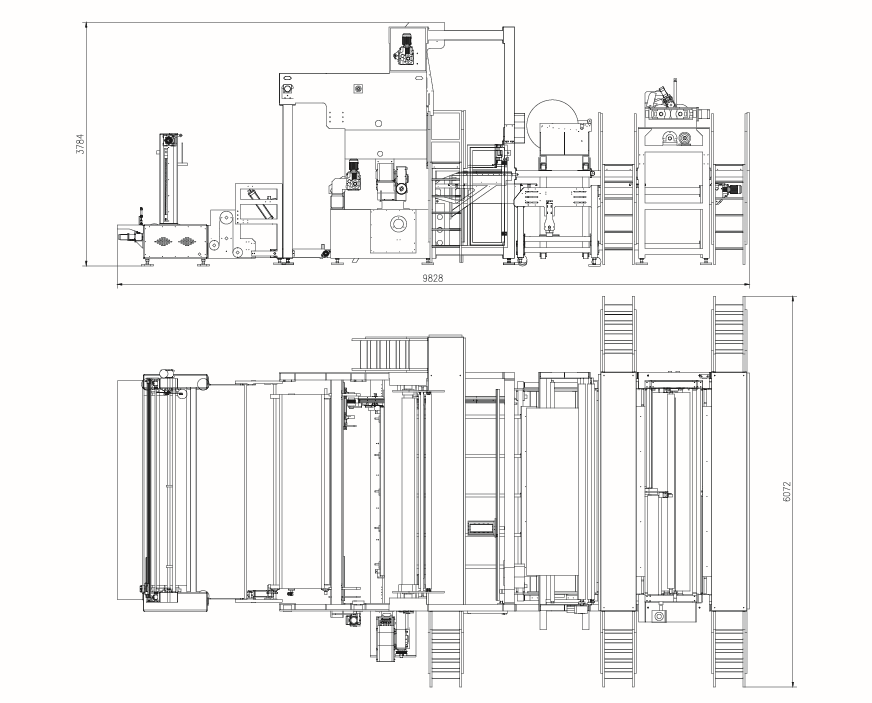

General assembly drawing

Specifications

| Width | 103 inch |

| Gauge | E7 |

| Speed | 50-1000r/min (The specific speed depend the products.) |

| Bar Number | 2 Bars |

| Pattern Drive | Split Pattern Disc |

| Warp Beam Support | 30 inches beam.EBC |

| Take-up Device | Electronic Take-up |

| Batching Device | Electronic Batching |

| Chopped Device | 1 Chopped Device,Servo System Controlling. |

| Weft-insertion System | Weft Insertion,Servo System Controlling. |

| Power | 28kW |

| This type* s machine could be personal designed |

Product Video

Your browser does not support video tags.

Product detail pictures:

Related Product Guide:

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Manufacturer of Chopped Strand Mat Manufacturing Process - YRS3-M-F-II Chopped Biaxial Warp Knitting Machine – Yixun , The product will supply to all over the world, such as: United Kingdom, Kyrgyzstan, Swiss, Each product is carefully made, it will make you satisfied. Our merchandise in the production process have got strictly monitored, because it is only to supply you the best quality, we'll feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

Write your message here and send it to us