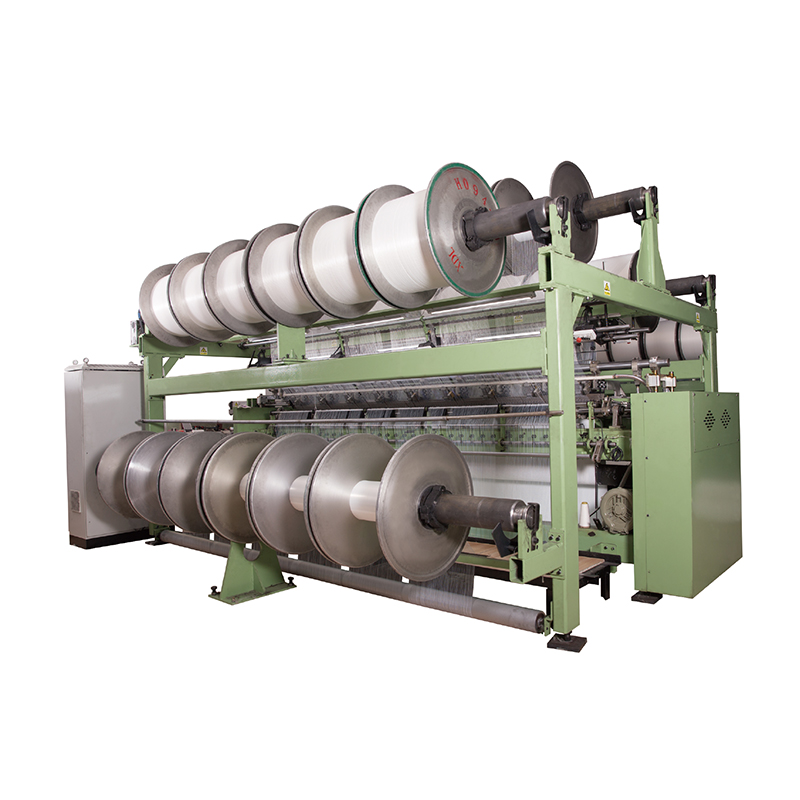

PriceList for Chopping Stitch Bonding Machine - FB Fiber-web Stitch-bonding Machine – Yixun

PriceList for Chopping Stitch Bonding Machine - FB Fiber-web Stitch-bonding Machine – Yixun Detail:

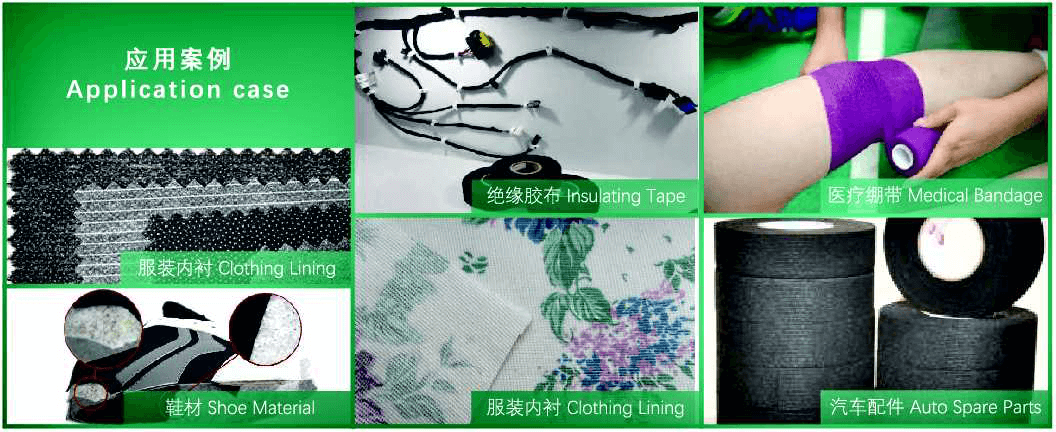

*Used for producing stitch bonded fabric,medical bandage,clothing interlining,Curtain Fabric.

Application Case

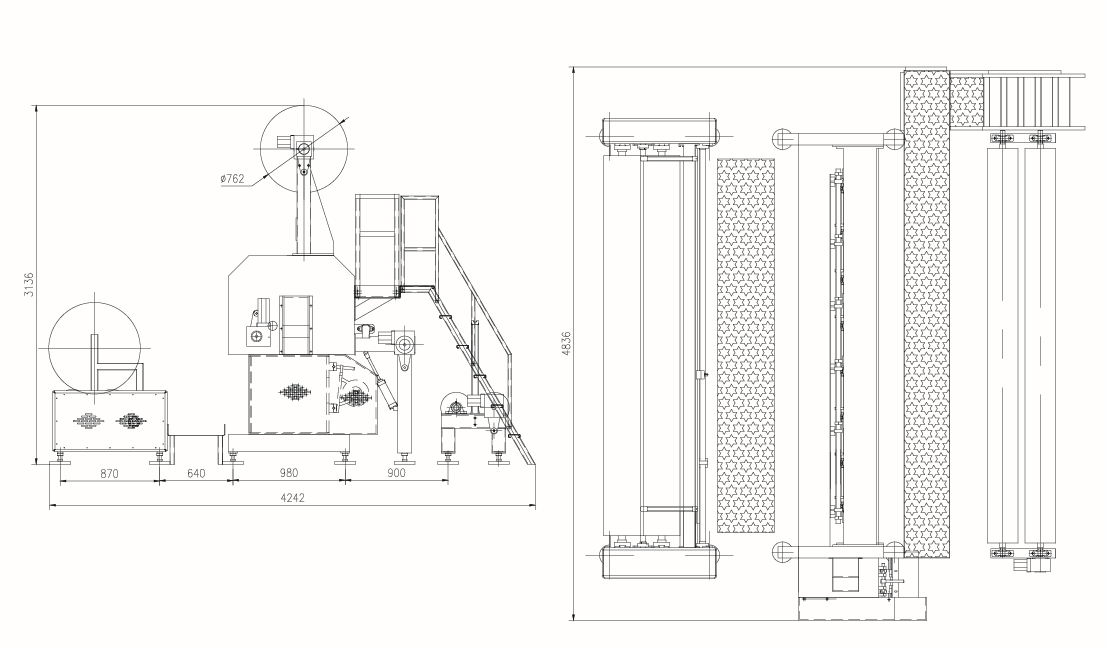

General assembly drawing

Specifications

| Width | 2800mm,3400mm,4400mm |

| Gauge | F7,F12,F14,F16,F18,F20,F22 |

| Speed | 50-1500r/min(The specific speed depend the products.) |

| Bar Number | 1 Bar(two bars) |

| Pattern Drive | Pattern Disc |

| Warp Beam Support | 30 inches beam,EBC |

| Take-up Device | Electronic Take-up |

| Batching Device | Electronic Batching |

| Power | 13kW(The power of machine 4400mm width is 18kW) |

| This type* s machine could be personal designed |

Product detail pictures:

Related Product Guide:

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for PriceList for Chopping Stitch Bonding Machine - FB Fiber-web Stitch-bonding Machine – Yixun , The product will supply to all over the world, such as: Mongolia, Costa Rica, Ghana, At Present, our merchandise have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

Write your message here and send it to us