15 Best Polyester Geogrid Insights for Global Buyers

Table of Contents

- Understanding Polyester Geogrids: Key Characteristics and Benefits

- Top Applications for Polyester Geogrids in Civil Engineering Projects

- Comparison of Polyester Geogrids with Other Geosynthetic Materials

- Global Market Trends: Demand and Supply of Polyester Geogrids

- Choosing the Right Polyester Geogrid for Your Project Needs

- Best Practices for Installing and Maintaining Polyester Geogrids

- Maximize Your Cleaning Efficiency: Discover the Versatile Benefits of Polyester Microfiber Towels and Multi-functional Batching Devices

- FAQS

- Conclusion

- Related Posts

As the world becomes more focused on green and efficient building materials, Polyester Geogrid has really started to stand out as a key player when it comes to soil stabilization and reinforcement. If you’ve been keeping an eye on industry trends, you’d notice that the global geogrid market is expected to grow at around 10.4% CAGR from 2021 to 2028. This surge is mainly fueled by more infrastructure projects around the globe and the rising demand for geosynthetics, especially in road construction and environmental efforts.

Here at DANYANG YIXUN MACHINERY CO., LTD, we’re really proud to be part of this wave of change. We specialize in cutting-edge multiaxial and biaxial warp knitting machines, designed specifically for making top-quality Polyester Geogrids. Thanks to our advanced tech and solid manufacturing processes, we make sure our customers get innovative, reliable solutions that match the evolving needs of the geosynthetics market.

Understanding Polyester Geogrids: Key Characteristics and Benefits

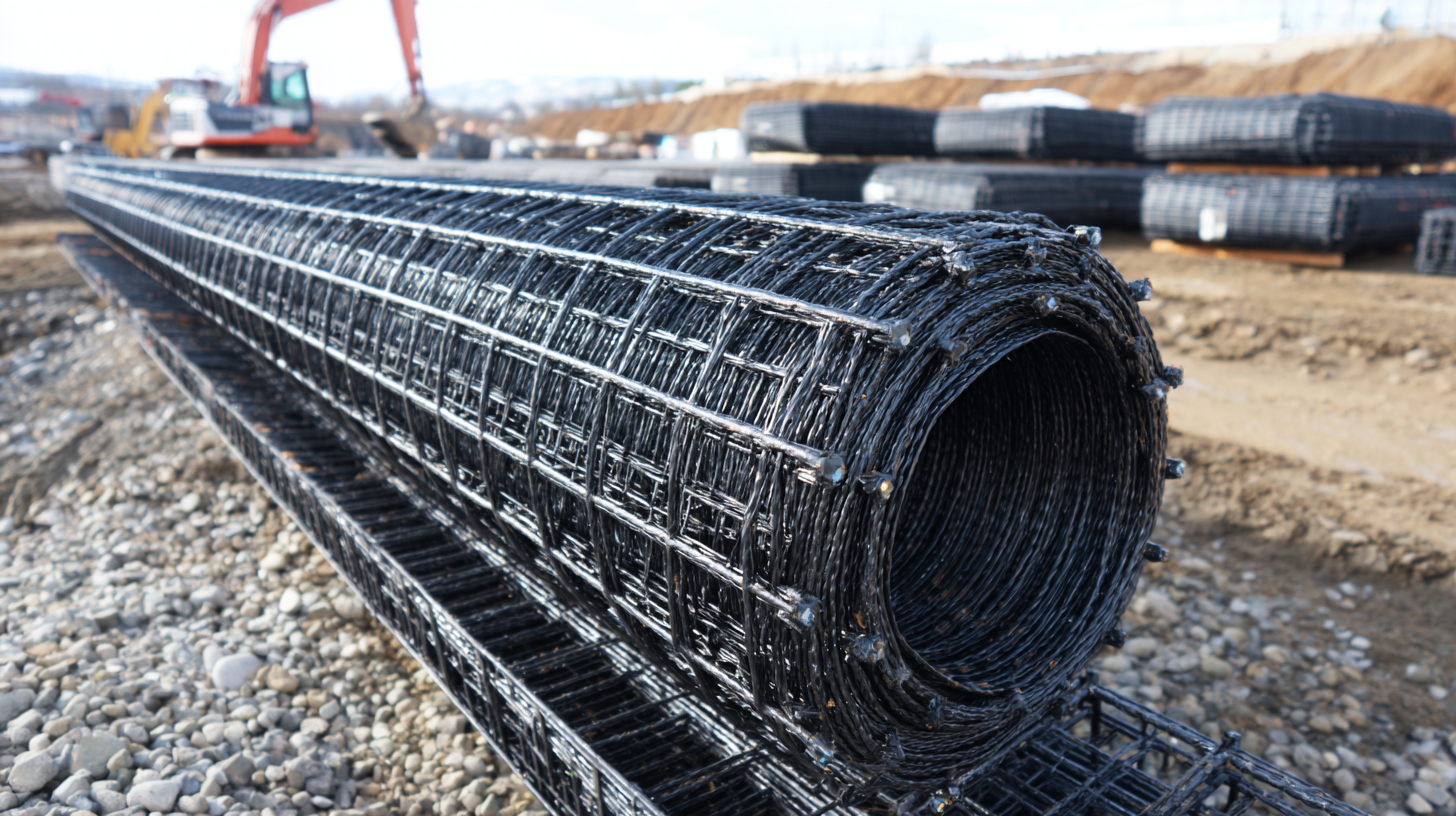

Polyester geogrids have really become a game-changer in civil engineering and construction these days. They offer so many benefits that help improve the durability and performance of infrastructure projects — stuff like making things last longer and stay stable. If you're a buyer anywhere around the world thinking about investing in good quality materials, it’s super helpful to get a handle on what makes these geogrids special. They’re made from tough polyester fibers, which give them amazing tensile strength, so they can effectively reinforce soil or keep slopes stable. Plus, they’re pretty lightweight but still stand up well against the elements—UV rays, chemicals, you name it. That means they’re not only effective but also a pretty cost-efficient choice for lots of different construction jobs.

Here at DANYANG YIXUN MACHINERY CO., LTD, we’re all about making advanced warp knitting machines that produce multiaxial and biaxial geogrids. Our state-of-the-art tech ensures each batch is top quality and precise—just what modern construction projects need. We're all about innovation, which helps our clients boost the performance of their projects without sacrificing sustainability. Understanding how polyester geogrids contribute to keeping infrastructure stable can really help buyers make smarter decisions tailored to their specific needs.

Top Applications for Polyester Geogrids in Civil Engineering Projects

Lately, you might have noticed that polyester geogrids are really making waves in civil engineering projects. It's pretty exciting because they’re such a big part of moving towards more sustainable construction. These geogrids are crucial—they help strengthen weak soils, improve stability, prevent erosion, and keep everything in place. And it’s not just small talk; research shows that the global market for geosynthetics is set for some serious growth, mainly thanks to the increasing need for durable infrastructure to support growing populations. For example, new tech in geogrids isn’t just about better load distribution in roads and transportation; it’s also helping prevent potholes down the line, which opens up some pretty cool opportunities, especially here in the U.S.

Plus, there’s some exciting projections coming out of South Asia. A recent report suggests that their geosynthetic market is going to grow like crazy between 2025 and 2035 because the region really needs modern infrastructure—fast. As polyester geogrids become more popular for being eco-friendly, they’re becoming pretty much indispensable in various civil engineering projects, whether it’s building roads or managing landfills.

Companies like Danyang Yixun Machinery Co., Ltd., are really leading the charge here—they’re making advanced multiaxial and stitch-bond warp knitting machines that produce top-notch geogrid materials. All in all, it kind of feels like a perfect storm—innovative manufacturing meets smart application—really helping us tackle today’s engineering challenges with a more eco-conscious mindset.

Comparison of Polyester Geogrids with Other Geosynthetic Materials

Lately, polyester geogrids have really been catching attention in the world of geosynthetics, especially when you compare them to other materials out there. People love them for their durability and stability — they’re pretty reliable for all sorts of jobs, like building roads or reinforcing soil. What’s cool is that, unlike the old-school materials, polyester geogrids tend to perform better when it comes to spreading out loads and lasting over the long haul. Their special geometric design helps them handle heavy overloads, which means they do a better job controlling settlement in unbound granular bases.

Recent studies really highlight how using geosynthetics, including polyester geogrids, can boost soil stability and help protect against erosion. There’s also some pretty exciting research into geocell reinforcements, showing they could be a game-changer in stopping long-term road issues like potholes. All these advances open up some awesome possibilities for the U.S. geosynthetics scene.

As more folks start seeing the benefits of these polymer-based solutions, especially as eco-friendly options, I think we’re gonna see civil engineers and industry pros adopting them more and more. Moving toward more sustainable building practices isn’t just good for the environment — it’s also about upgrading our infrastructure in smarter, more efficient ways.

Global Market Trends: Demand and Supply of Polyester Geogrids

The global market for polyester geogrids is really picking up steam lately. A big reason? There's growing demand for more sustainable and durable construction solutions out there. Companies are on the lookout for innovative ways to make infrastructure last longer, and polyester geogrids are quickly becoming a top choice for reinforcement. They're great at improving soil stability and helping prevent potholes—especially useful for road construction and rehab projects here in the U.S. geosynthetics scene.

Adding in geogrid composites is actually a pretty smart move when it comes to long-term pavement performance. These materials do a solid job at spreading out loads and reducing deformation, which basically boosts the entire structure’s strength. If you're in the market, now’s a good time to consider investing in high-quality geogrids that tick all the right boxes for industry standards.

**Quick Tips for Buyers:**

1. Take a good look at the specs and performance data of different polyester geogrids—make sure they’re up to snuff for your specific project.

2. It’s worth checking out manufacturers who are into advanced knitting tech; their products tend to be more reliable and better quality in the long run.

3. Keep an eye on regional market trends and new tech popping up in geosynthetics. Staying updated helps you make smarter buying decisions, aligned with global best practices.

Global Demand for Polyester Geogrids (2023)

Choosing the Right Polyester Geogrid for Your Project Needs

So, when you're trying to pick the right polyester geogrid for your project, it’s really important to understand what your specific needs are. Polyester geogrids are pretty popular because they have high tensile strength and don't stretch much, which makes them great for reinforcing the base layers in things like road building, retaining walls, or stabilizing embankments. I came across a report from MarketsandMarkets that says the geogrid market could hit around $1.6 billion by 2026—that’s mainly because there's increasing demand for more eco-friendly infrastructure solutions.

So, when you're trying to pick the right polyester geogrid for your project, it’s really important to understand what your specific needs are. Polyester geogrids are pretty popular because they have high tensile strength and don't stretch much, which makes them great for reinforcing the base layers in things like road building, retaining walls, or stabilizing embankments. I came across a report from MarketsandMarkets that says the geogrid market could hit around $1.6 billion by 2026—that’s mainly because there's increasing demand for more eco-friendly infrastructure solutions.

One thing you really shouldn’t overlook is the environmental conditions of your site. Polyester geogrids work especially well in places where soil erosion might be a problem, thanks to their resistance to chemicals and UV rays. A study from the International Journal of Geo-Engineering even mentioned that using polyester geogrids can cut down the thickness of the aggregate base layer by up to 30%, saving both materials and money. Oh, and don’t forget to match the geogrid's specs with your project’s load requirements. Using the right one that can handle vertical and lateral stresses is key to making sure your structure stays solid and lasts long-term.

Best Practices for Installing and Maintaining Polyester Geogrids

When you're working with polyester geogrids, whether it's installing them or taking care of them later on, there are a few best practices that can really make a difference in how long they last and how well they perform. First off, it’s super important to get the site all set up properly. That means doing some solid grading and making sure the soil is well-compacted so you have a stable base to work on. Oh, and a quick tip — try to avoid installing the geogrids when it’s soaking wet outside. Too much moisture can mess with the soil’s stability and might mess up the whole grid system.

Also, paying attention to how you align everything during installation is key. If the geogrid isn’t straight or properly aligned, it can cause stress points that might lead to damage down the line. Using marking tools or some kind of visual guide can really help keep things on track. Once everything's installed, don’t forget to check in regularly. A quick inspection now and then can catch potential problems early before they turn into big issues.

By the way, DANYANG YIXUN MACHINERY CO., LTD is a big player when it comes to making top-notch multiaxial and biaxial warp knitting machines. These machines are pretty much essential for producing sturdy polyester geogrids. Investing in reliable equipment really pays off — it means better quality products and smoother performance in the field. Plus, keeping the machinery well-maintained and making sure the operators are properly trained can up your game when it comes to production quality. All of this lines up with best practices for installation and upkeep, making sure everything runs as smoothly as possible.

Maximize Your Cleaning Efficiency: Discover the Versatile Benefits of Polyester Microfiber Towels and Multi-functional Batching Devices

In today's fast-paced world, maximizing cleaning efficiency is essential, and no tool epitomizes this more than polyester microfiber towels. These versatile cleaning agents not only enhance the cleanliness of surfaces but also contribute significantly to sustainability. Made from high-tech materials, these towels can effortlessly capture dust and grime while requiring minimal cleaning solutions, making them ideal for both commercial and residential spaces. Their durability ensures that they can be washed and reused numerous times, providing cost-effective solutions for any cleaning task.

In conjunction with microfiber towels, multi-functional batching devices play a crucial role in optimizing production processes, especially when creating a variety of fabrics like non-woven, stitch bonded, and woven cloths. The advanced batching systems, which feature a friction and center one-piece take-up design with a batching outside diameter of w2000mm, streamline operations. These specifications allow for width adjustments, facilitating the efficient production of various fabric types. Whether for cleaning purposes or fabric production, integrating these tools can significantly elevate operational efficiency and product quality, resulting in cleaner environments and innovative textiles.

FAQS

: Polyester geogrids are primarily used for reinforcing weak soil to provide enhanced stability, erosion protection, and effective soil retention in various civil engineering applications, including roadway construction and landfill projects.

The increasing demand for durable infrastructure to support rising populations and the trend towards sustainable construction practices are driving the growth of the polyester geogrid market.

Polyester geogrids are known for their robustness and stability, offering superior performance in load distribution and long-term durability compared to traditional materials, making them more effective for various applications.

The global geosynthetics market, particularly in South Asia, is expected to witness remarkable growth, driven by the urgent need for modern infrastructure solutions, creating opportunities for polyester geogrids.

DANYANG YIXUN MACHINERY CO., LTD is providing advanced multiaxial and stitch bonding warp knitting machines, which enable the production of high-quality polyester geogrid materials, supporting innovative geosynthetic applications.

Polyester geogrids enhance soil stability and erosion protection, preventing long-term road damages, such as potholes, thus contributing to the sustainability of infrastructure.

The awareness of the environmental benefits of using polymer-based geogrids as eco-friendly alternatives is leading more civil engineers and industry professionals to adopt these efficient materials in their projects.

Polyester geogrids enhance soil stability and provide effective erosion protection, making them essential in various civil engineering applications to prevent soil loss and degradation.

The unique geometrical properties of polyester geogrids enhance their ability to withstand overload conditions and improve settlement behavior in unbound granular base layers, contributing to their effectiveness in construction applications.

The integration of geosynthetic materials, including polyester geogrids, has been shown to enhance soil stability, erosion protection, and overall infrastructure performance, creating exciting opportunities in the field.

Conclusion

When it comes to civil engineering, Polyester Geogrids have really stepped into the spotlight as a game-changer. They come with unique features and a bunch of benefits that make many projects smoother—from making soil more stable to spreading out loads in road construction, these geogrids are pretty much essential. Knowing where they’re most useful helps engineers make the most of their strengths and get better results on their projects.

Plus, if you compare Polyester Geogrids to other geosynthetic options, it’s pretty clear they often come out on top in certain situations. That’s why the demand for them is growing worldwide. As trends shift and new stuff comes out, it’s really important for buyers to consider the key factors when picking the right Polyester Geogrid for their specific project. And don’t forget, doing things right during installation and maintenance is crucial if you want these materials to perform well and last a long time.

Here at DANYANG YIXUN MACHINERY CO., LTD, we’re ready to support you every step of the way, providing top-quality machines to produce Polyester Geogrids and other cutting-edge materials. We’re all about helping you get the best results, no matter what your project needs.

Related Posts

-

A Comprehensive Guide to Choosing the Right Multiaxial Fabric Cloth for Your Project

-

Challenges Encountered with Glass Fiber Grille in Global Market

-

7 Essential Tips for Choosing the Right Industrial Fabric for Your Projects

-

Unlocking Efficiency: Essential Strategies for Sourcing Spare Parts for Warp Knitting Machines

-

The Ultimate Guide to Understanding Geogrid Material for Construction Success

-

Innovative Applications of Multi-Axial Carbon Fiber in Aerospace and Automotive Industries