7 Essential Tips for Choosing the Right Industrial Fabric for Your Projects

Table of Contents

- Key Considerations for Selecting Industrial Fabrics: Durability and Performance Metrics

- Understanding Fabric Specifications: Weaving Techniques, Fiber Types, and Their Impact

- Evaluating Environmental Resistance: How Fabrics Stand Up to Moisture, UV, and Temperature Change

- Cost-Effectiveness: Analyzing Material Lifespan vs. Initial Investment in Industrial Fabrics

- Sustainability in Fabric Choices: The Growing Importance of Eco-Friendly Materials and Practices

- Maximizing Production Efficiency: Insights from the Latest Global Textile Machinery Report on YRS3-M-V Bi-Axial Warp Knitting Technique

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing world of manufacturing, picking the right industrial fabrics is more important than ever for making sure your project turns out well. According to a report from MarketsandMarkets, the global market for industrial textiles is expected to hit around $185 billion by 2025, growing at a steady rate of about 4.3% each year. That really highlights just how crucial quality textiles are—think automotive, aerospace, construction—you name it. At DANYANG YIXUN MACHINERY CO., LTD, we focus on building top-notch multiaxial and biaxial warp knitting machines, including stitch bonding and towel warp knitting machines, designed for industries that rely on high-performance stuff like glass fiber, combo mats, and chopped strand mats. Choosing the right fabric isn’t just about durability; it affects the whole project’s efficiency. So, it’s pretty important for experts like you to know what factors matter most when you’re making that call.

Key Considerations for Selecting Industrial Fabrics: Durability and Performance Metrics

When you're choosing the right industrial fabrics for your projects, things like durability and performance are absolutely key. I mean, these factors really tell you how long the materials will last and how well they'll hold up under tough conditions.

Take recent tech with basalt fiber reinforced polymers—BFRPs, for short—they've been making waves by dramatically improving the safety and lifespan of older structures. They've got a real knack for fixing common headaches like wall cracks and concrete deterioration, which means they’re a pretty solid option for all kinds of industrial uses.

On the manufacturing side of things, picking the right knitting machines can make a huge difference in the quality and performance of what you produce. Companies like ours focus on multiaxial and biaxial warp knitting machines—they’re really the backbone for creating innovative fabrics. With that kind of advanced equipment, we can craft textiles that meet the highest durability standards, making sure that your projects have access to the best materials out there. As industries keep evolving, understanding these key points is super helpful—it’ll totally guide you when choosing industrial fabrics that really fit your specific needs.

Understanding Fabric Specifications: Weaving Techniques, Fiber Types, and Their Impact

Hey, so when you're picking out the right industrial fabric for your project, it’s pretty important to get a good grip on fabric specs. The way the fabric is woven really affects how strong, durable, and just how it looks overall. You’ve got different weaving styles like plain weave, twill, and satin — each with their own perks. For example, plain weaves are super stable and are often used when you need something really tough. On the other hand, twill weaves are a bit more flexible and drape nicely, which makes them perfect for items that need to conform to different shapes.

And don’t forget about the fibers themselves! Natural fibers like cotton and linen are breathable and comfy — great if you want moisture-wicking properties. But synthetic options like polyester and nylon are way tougher, resisting tough environmental conditions and offering higher tensile strength. Once you understand how the fiber type and weaving style work together, you’ll be better equipped to choose something that really fits what you’re aiming for — whether it’s for rugged industrial use or something lightweight and specialized. It’s all about finding the right combo that matches your needs.

7 Essential Tips for Choosing the Right Industrial Fabric for Your Projects

| Fabric Type | Fiber Content | Weaving Technique | Durability | Applications |

|---|---|---|---|---|

| Canvas | Cotton/Polyester Blend | Plain Weave | High | Tents, Tarps, Bags |

| Nylon | 100% Nylon | Twill Weave | Medium | Outdoor Gear, Industrial Covers |

| Polyester | 100% Polyester | Satin Weave | High | Apparel, Home Textiles |

| Ripstop | Cotton/Nylon Blend | Ripstop Weave | Very High | Military, High-performance Gear |

| Vinyl | PVC Coated | Coated Fabric | High | Awning, Covers, Tarps |

Evaluating Environmental Resistance: How Fabrics Stand Up to Moisture, UV, and Temperature Change

When you're choosing the right industrial fabric, it's really crucial to think about how well it can stand up to the elements. Fabrics often face all sorts of weather — moisture, UV rays, big temperature swings — and these can seriously affect how long they last and how well they perform. I came across a report from the Industrial Fabrics Association International (IFAI) that mentioned fabrics with high UV resistance can keep their color and structure intact for up to 10 years, even when exposed to direct sunlight. That’s pretty impressive, especially if you’re looking at outdoors stuff like tents, awnings, or tarps.

And it’s not just about UV. Moisture resistance is just as important, especially in industries where stuff gets wet often. A study by the American Association of Textile Chemists and Colorists found that fabrics treated for water repellency can handle rain and humidity pretty well — some even rated over 1000 mm of water resistance. Plus, if you're dealing with super hot or cold conditions, you’ll want fabrics that can handle temperature swings. Apparently, some of these fabrics can perform in temperatures from -40°F all the way up to over 250°F — crazy, right? Making sure you account for these environmental factors means picking a fabric that will not just do the job but actually excel under tough conditions. Basically, a little research into these aspects can make a big difference in getting the right fabric for your project.

Environmental Resistance of Industrial Fabrics

Cost-Effectiveness: Analyzing Material Lifespan vs. Initial Investment in Industrial Fabrics

When you're picking out industrial fabrics, it’s pretty important to think about how long they last versus what you’re actually paying upfront. I read from the Technical Textiles Association that high-quality fabrics can last anywhere from 5 to 10 years longer than cheaper options. That’s a pretty big deal because it means you’re not constantly replacing them, which can really add up in the long run. Actually, going for more durable materials can save you about 20-30% over the entire lifecycle — definitely making it a smart move if you’re trying to keep things running smoothly and save some cash.

Plus, it’s worth considering how your initial spend lines up with how long the fabric is expected to last. A study from the Fabricators & Manufacturers Association pointed out that while cheaper fabrics might seem like a bargain at first, they usually end up costing more in maintenance and replacements down the line. For example, synthetic fabrics that are a bit pricier upfront often stay in better shape longer, resisting UV damage and staying sturdy. That means less downtime for repairs and fewer headaches. So, getting a good grip on the balance between what you pay now and what you’ll save over time is super important when choosing the right industrial fabric for your needs.

Sustainability in Fabric Choices: The Growing Importance of Eco-Friendly Materials and Practices

You know, sustainability when it comes to fabric choices has really become a big deal for a lot of industries lately. People are more aware of environmental issues, and there's definitely a growing demand for eco-friendly options. I read somewhere—Grand View Research, I think—that the global market for eco-friendly fabrics is probably gonna hit around $85 billion by 2027, growing at about 11.4% each year. Crazy, right? This shift isn’t just about what consumers want anymore; it's a wake-up call for industries to start adopting greener, more responsible practices.

In the industrial world, opting for sustainable fabrics can really make a difference—cutting down carbon footprints and waste quite a bit. Things like organic cotton, recycled polyester, or hemp can cut greenhouse gases by up to half compared to traditional materials. Plus, using production methods that save water and cut down on chemicals not only benefits the environment but also helps build better relationships with local communities. When companies incorporate eco-friendly materials into their products, they're not just helping the planet—they’re also boosting their brand image and showing that they care about what socially conscious folks value these days.

Maximizing Production Efficiency: Insights from the Latest Global Textile Machinery Report on YRS3-M-V Bi-Axial Warp Knitting Technique

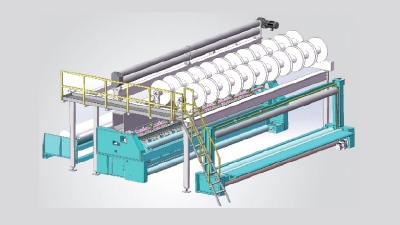

The latest advancements in textile machinery have brought forth the YRS3-M-V bi-axial warp knitting technique, positioning itself as a game-changer for maximizing production efficiency. This innovative warp knitting machine excels in creating reinforcement geo composites through a one-time forming process, streamlining production and offering significant time savings. With the ability to produce high-quality materials, manufacturers can now respond faster to evolving market demands and enhance their product offerings.

Equipped with impressive specifications, the YRS3-M-V boasts a versatile range of gauges (E3, E6, E9) and widths (186″, 225″), making it suitable for diverse applications across the textile industry. The machine's speed, ranging from 50 to 1200 revolutions per minute, is adaptable to the specific demands of various products, allowing for greater flexibility in production schedules. As enterprises strive for efficiency and quality, the adoption of this advanced knitting technique represents a significant step forward in optimizing manufacturing processes.

FAQS

: The common weaving techniques include plain weave, twill weave, and satin weave, each offering different benefits in terms of strength, durability, and appearance.

Plain weave fabrics provide excellent stability and are often used in applications requiring utmost durability.

Twill weaves enhance flexibility and draping abilities, making them ideal for items that need to conform to various shapes.

Common types of fibers include natural fibers like cotton and linen, which are breathable and comfortable, and synthetic fibers like polyester and nylon, which offer superior tensile strength.

Choosing sustainable fabrics can significantly reduce carbon footprints and waste, lowering greenhouse gas emissions by up to 50% compared to conventional materials.

The global eco-friendly fabric market is expected to reach $85 billion by 2027, expanding at a compound annual growth rate (CAGR) of 11.4%.

The adoption of organic cotton, recycled polyester, or hemp often results in reduced chemical usage and water conservation, contributing to a healthier environment.

Today’s socially conscious consumers demand eco-friendly options, prompting industries to integrate sustainable materials to align with these values and enhance brand image.

Understanding fabric specifications, including weaving techniques and fiber types, helps in making informed decisions that meet specific project requirements, whether for heavy-duty or lightweight uses.

Integrating eco-friendly materials not only contributes to environmental preservation but also enhances the brand image, aligning with the values of today's consumers.

Conclusion

Picking the right industrial fabric really matters if you want your projects to succeed. There are a few key things you should keep in mind. First off, take a close look at how durable and high-performing the fabrics are — think about the weaving techniques used and the types of fibers, making sure they suit what you need. It’s also super important to understand how fabrics hold up against the elements—stuff like moisture, UV rays, and temperature changes—so you get something that lasts. And don’t forget about costs! It’s worth comparing how long the fabric will last with what you're paying upfront to see if it’s worth it in the long run.

Sustainability’s becoming a big deal too. Going for eco-friendly materials not only helps the environment but can actually boost your project’s reputation. By the way, DANYANG YIXUN MACHINERY CO., LTD is great if you’re looking for top-notch knitting machines designed for all sorts of industrial fabrics. They focus on quality and performance, making sure you get what you need. Keep these things in mind, and you'll be making smarter choices that benefit both your work and the planet—and that’s pretty satisfying, right?