Innovative Applications of Multi-Axial Carbon Fiber in Aerospace and Automotive Industries

Table of Contents

- Understanding Multi-Axial Carbon Fiber: Properties and Benefits for Aerospace and Automotive

- Key Applications of Multi-Axial Carbon Fiber in Aerospace Engineering and Aircraft Design

- Advancements in Automotive Manufacturing: The Role of Multi-Axial Carbon Fiber

- Comparative Analysis: Multi-Axial Carbon Fiber vs. Traditional Materials in Industry

- Challenges and Solutions in Implementing Multi-Axial Carbon Fiber Technology

- Future Trends: The Evolving Impact of Multi-Axial Carbon Fiber on Industry Innovation

- Exploring the Advantages of the YRS3-3M-C Carbon Fiber Multi-Axial Warp Knitting Machine in Modern Manufacturing

- FAQS

- Conclusion

- Related Posts

You know, both the aerospace and automotive worlds are really going through a big change right now—kind of like a technology upgrade, if you will. One of the coolest things popping up is Multi-Axial Carbon Fiber. Honestly, it’s a total game-changer thanks to its incredible strength combined with being super lightweight. I read in a recent industry report from MarketsandMarkets that the market for composite materials might hit around 146.5 billion USD by 2026, and a lot of that growth is coming from new fiber tech. DANYANG YIXUN MACHINERY CO., LTD isn’t just sitting back either—they’re leading the charge with their advanced machinery for making these high-performance fabrics. Incorporating Multi-Axial Carbon Fiber really helps make parts stronger and more durable, which means cars and planes can be more fuel-efficient and better for the environment. As everyone’s looking for lighter, tougher materials, I think we’ll see even more applications in these industries. It’s pretty exciting to watch how these innovations are pushing both how things are made and how well they perform.

Understanding Multi-Axial Carbon Fiber: Properties and Benefits for Aerospace and Automotive

You know, multi-axial carbon fiber has really shaken things up in both the aerospace and automotive worlds. It’s all about those incredible properties it offers. Folks have been using it to develop lightweight, fiber-reinforced composites that not only boost mechanical performance but also cut down weight—super important in aerospace where safety and efficiency are king. Industry reports talk about how carbon fiber-reinforced polymers, or CFRPs, have such a high strength-to-weight ratio that some are reducing weight by as much as half compared to older materials. That’s a game-changer for modern aircraft design.

On the automotive side of things, the cool thing is how versatile multi-axial carbon fiber is. Car manufacturers can now build components that are tough as nails, plus resistant to heat and chemicals—which means they last longer and perform better under tough conditions. Plus, as manufacturing tech improves, producing CFRP parts has become more efficient, making it possible to create vehicle parts that really boost performance and save fuel. As things keep moving forward, it’s pretty exciting to see how multi-axial carbon fiber will keep pushing boundaries, leading to safer, smarter, and more sustainable vehicles and aircraft. Things are definitely looking bright in this space!

Key Applications of Multi-Axial Carbon Fiber in Aerospace Engineering and Aircraft Design

Multi-axial carbon fiber composites are really shaking up the aerospace engineering and aircraft design worlds. They've got an incredible strength-to-weight ratio and are super durable, which is a game-changer. Recent studies show that these fiber-reinforced materials aren't just about making structures stronger—they also help tackle failure issues under all sorts of conditions, like heat, oxidation, and mechanical stress. People are using these composites more and more to build lightweight structures, which means airlines can save fuel and cut down on emissions—something the industry’s really aiming for with all the sustainability talk.

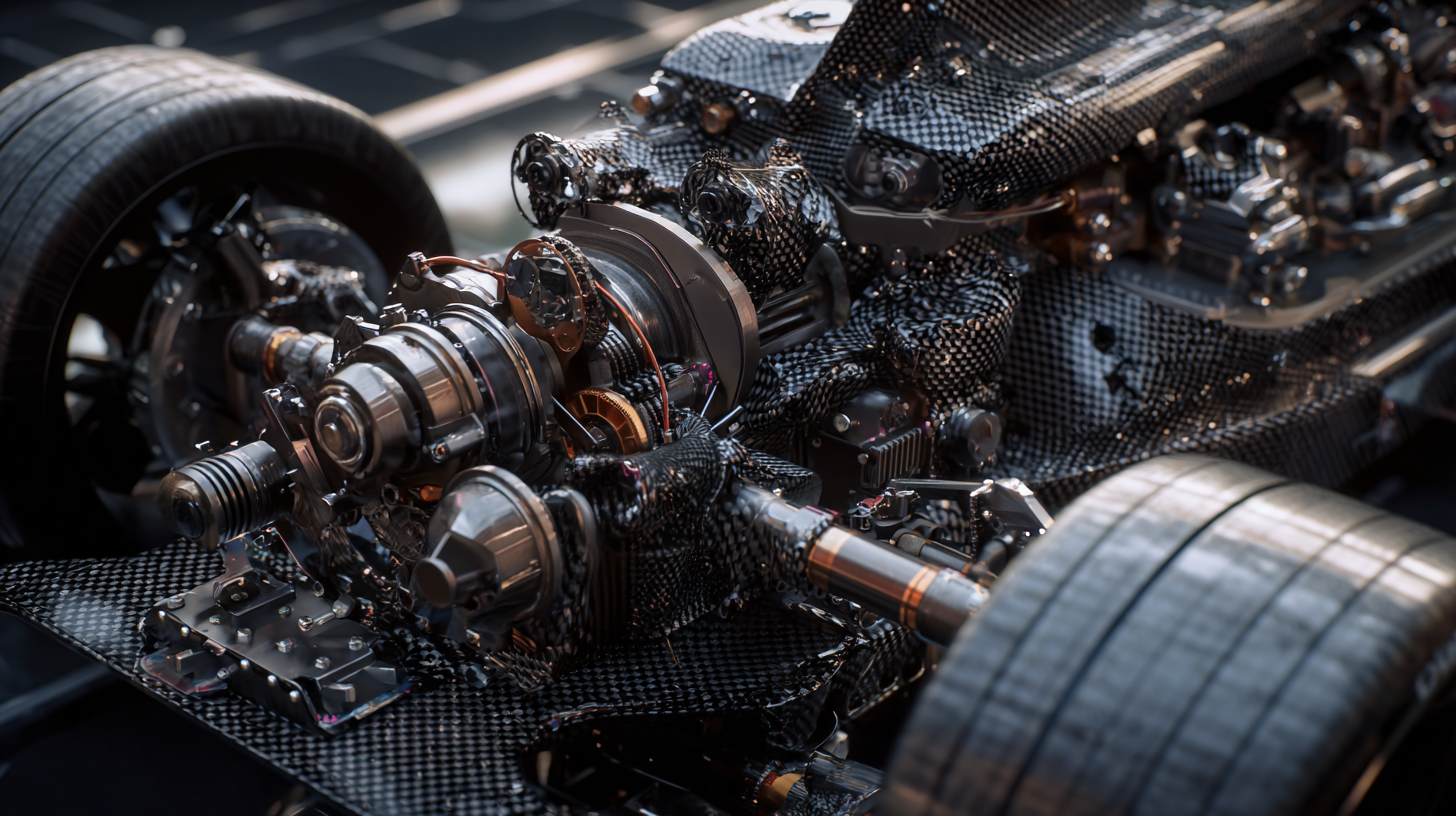

On the automotive side of things, multi-axial carbon fiber is also making waves. It's used in parts that need to be really stiff and resistant to tough road conditions. Fitting these materials into cars not only makes them lighter but also safer—since they absorb impact energy better. Some recent research into fatigue behavior shows that these composites keep performing well even when subjected to varying stress frequencies, making them perfect for critical automotive parts.

**Tip:** When you're thinking about adding multi-axial carbon fiber into your design, it’s smart to really consider the loads the part will face throughout its life. That way, you can tweak things to get the best performance and durability. Also, using tech like embedded fiber optic sensors can give you real-time insights into how the structure’s holding up—helping to boost safety and reliability in aerospace applications.

Innovative Applications of Multi-Axial Carbon Fiber in Aerospace and Automotive Industries

Advancements in Automotive Manufacturing: The Role of Multi-Axial Carbon Fiber

The automotive world is really going through some big changes lately, thanks to multi-axial carbon fiber. This material is pretty incredible—it's lightweight but super strong and durable. Recent breakthroughs in how we make composites, like optimizing fiber arrangements and topology, are really pushing vehicle performance to the next level. By carefully placing fibers, manufacturers can boost the strength and stiffness of different parts, which means safer, more efficient, and lighter cars. The market for carbon fiber tapes alone is expected to hit around $9.66 billion by 2032, showing just how much interest there is in lightweight, high-performance materials right now.

At the same time, new manufacturing methods like pultrusion are changing the game, making production both cheaper and more eco-friendly. Plus, the emergence of non-stitched multiaxial carbon fiber fabrics offers great stability—comparable to traditional stitched fabrics—giving designers even more flexibility. As demand for lightweight, advanced materials continues to grow, the automotive industry is really zooming in on these innovations to develop next-gen vehicles. These cars aren’t just about performance—they also aim to meet sustainability goals, which is pretty exciting.

Comparative Analysis: Multi-Axial Carbon Fiber vs. Traditional Materials in Industry

Lately, multi-axial carbon fiber is really making waves in both the aerospace and automotive worlds. It’s kind of a big deal, especially when you compare it to the usual metals and plastics we’ve used before. Recent studies are saying that these carbon fiber composites are not only super strong but also much lighter, which makes them perfect for parts that need to have a high strength-to-weight ratio. Just look at 3D braided carbon fiber composites—more and more, they’re replacing older materials in things like transmission components. They’re able to handle axial loads and fatigue really well, which means we’re seeing a pretty big shift in how things are made—lighter, tougher materials are taking center stage over the old-school options.

If you’re thinking about using multi-axial carbon fiber in your manufacturing process, a good starting point is to really understand what your specific performance needs are. Whether you’re working with soft actuators or precise components, knowing how this material reacts under different loads can really help you fine-tune your designs. And the cool part? The automated pultrusion process used here not only cuts down costs but is also better for the environment—something more companies are trying to focus on these days.

Another exciting thing to keep an eye on is how additive manufacturing, or 3D printing, is being combined with fiber-reinforced composites. This combo opens up all kinds of possibilities for creating complex shapes and gives designers a lot more flexibility. As you explore the potential of multi-axial carbon fiber, think about how these new tools and techniques could help you streamline production and make your products more functional and innovative.

Challenges and Solutions in Implementing Multi-Axial Carbon Fiber Technology

You know, bringing multi-axial carbon fiber tech into the aerospace and automotive worlds is pretty exciting—there are some real new benefits, but also a fair share of challenges. As these industries keep pushing for lighter yet still super strong materials, using multi-axial carbon fibers seems like a promising way to boost structural performance. That said, the whole process isn’t exactly straightforward; it demands careful planning when it comes to design, choosing the right materials, and manufacturing. Sometimes, it’s a real balancing act to get the components to be both strong and reliable without running into issues.

For companies thinking about jumping into this tech, it’s really important to understand and tackle the tricky parts of working with composites. For example, investing in advanced automated systems for non-destructive testing can go a long way—these tools help make sure the materials are solid without slowing down production. Also, tweaking the fiber paths during the design phase can really improve the mechanical properties of the finished product.

Pro tip: Check out the latest in 3D printing tech that uses multi-axial carbon fiber—you might be surprised at how it can help create custom parts that are both lightweight and super strong. And don’t forget, working with specialists in fiber path optimization can really give you a boost in maximizing your composite structures’ performance.

Future Trends: The Evolving Impact of Multi-Axial Carbon Fiber on Industry Innovation

These days, industries are really pushing for lighter yet stronger materials, and it looks like multi-axial carbon fiber is turning out to be a total game-changer—especially in aerospace and automotive fields. This high-tech composite is praised for its incredible strength-to-weight ratio, and it’s now being woven into designs that aim for top-notch performance and efficiency. Because it can handle loads from multiple angles, engineers are actually able to push the limits of aircraft and vehicle design. It means vehicles are not only tougher and safer but also lighter, which helps cut down on fuel costs. Plus, all of this is a step forward for sustainability, which is becoming more and more important in today’s manufacturing world.

Looking ahead, I think the role of multi-axial carbon fiber is only going to grow. As technology gets better, especially with manufacturing processes becoming cheaper and more efficient, we’ll see this material popping up in even more parts of the aerospace and auto industries. Things like 3D printing using carbon fibers and hybrid composites are coming soon, and they’re set to totally change how vehicles and planes are built. This evolution isn’t just about material science—it's inspiring new design ideas that focus on balancing performance with sustainability. Overall, I believe this stuff will become a key part of the industry’s future innovations.

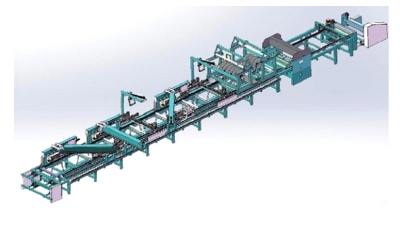

Exploring the Advantages of the YRS3-3M-C Carbon Fiber Multi-Axial Warp Knitting Machine in Modern Manufacturing

The YRS3-3M-C Carbon Fiber Multi-Axial Warp Knitting Machine stands out as a transformative innovation in modern manufacturing, particularly in the production of multi-layer and multi-directional carbon fiber warp knitting fabrics. This advanced machine’s ability to operate widths of 50 to 100 inches, paired with a range of gauges including E5 and E6, allows for a versatile approach to fabric design that meets the diverse needs of various industries.

Operating at impressive speeds of 50 to 600 revolutions per minute, the YRS3-3M-C is engineered to maximize efficiency while ensuring high-quality output. What sets this machine apart is its customizable weft-insertion device that can be tailored to specific product requirements, enhancing the overall adaptability of fabric production. This means manufacturers can produce complex, tailored fabrics that meet the stringent demands of aerospace, automotive, and sports equipment sectors, while also ensuring that production remains flexible and responsive to changing market needs.

Incorporating the YRS3-3M-C into the production line not only boosts operational efficiency but also elevates the quality of end products, making it an essential asset for any modern manufacturing facility invested in leveraging the properties of carbon fiber. By embracing such advanced technology, manufacturers can lead the way in fabric innovation, reinforcing their competitive edge in a rapidly evolving marketplace.

FAQS

: Multi-axial carbon fiber composites provide high strength-to-weight ratios, exceptional durability, and enhance structural integrity while addressing failure mechanisms under various conditions, contributing to fuel savings and reduced emissions in the aerospace sector.

In the automotive sector, these composites offer superior stiffness, resistance to harsh conditions, and the ability to absorb energy during impacts, making vehicles lighter and safer.

Investing in monitoring technologies such as embedded fiber optic sensors can provide real-time insights into the structural health of aerospace components, improving safety and reliability.

Multi-axial carbon fiber composites exhibit superior mechanical properties and weight reduction, making them ideal for applications requiring high strength-to-weight ratios, thereby gradually replacing traditional materials in various industries.

Focus on the specific load conditions expected throughout the component's lifecycle to optimize material performance and longevity, while understanding the material's behavior under different loading conditions.

The automated pultrusion process emphasizes cost efficiency and sustainability, making it a key factor for businesses looking to enhance product performance while reducing their environmental footprint.

The integration of additive manufacturing techniques with fiber-reinforced composites allows for complex shapes and design flexibility, streamlining production processes and enhancing product functionality.

The lightweight and durable characteristics of multi-axial carbon fiber composites contribute to significant fuel savings and reduced emissions, aligning with the aviation industry's sustainability goals.

Conclusion

Multi-axial carbon fiber is truly shaking things up in the aerospace and auto industries. Its unique qualities—like being super lightweight yet incredibly strong and durable—are making it a go-to material lately. No joke, this stuff is game-changing, especially in aircraft design, because it helps manufacturers build more efficient, high-performance planes. Same goes for cars; by incorporating multi-axial carbon fiber into manufacturing, companies are crafting vehicles that are lighter but way tougher, which means better fuel economy and safer rides.

That said, switching over from traditional materials to this high-tech fiber isn’t all smooth sailing. Costs can be high, and figuring out how to actually integrate it into existing processes is a bit tricky. Luckily, folks are working on solutions to make this transition easier and more seamless, so industries can really unlock the full potential of this innovative material. Looking ahead, it’s exciting to see how multi-axial carbon fiber will continue to push innovation across the board. And here at DANYANG YIXUN MACHINERY CO., LTD, we’re right there in the mix, supporting this change with advanced warp knitting machines designed specifically for this type of fiber. It’s an exciting time, for sure!